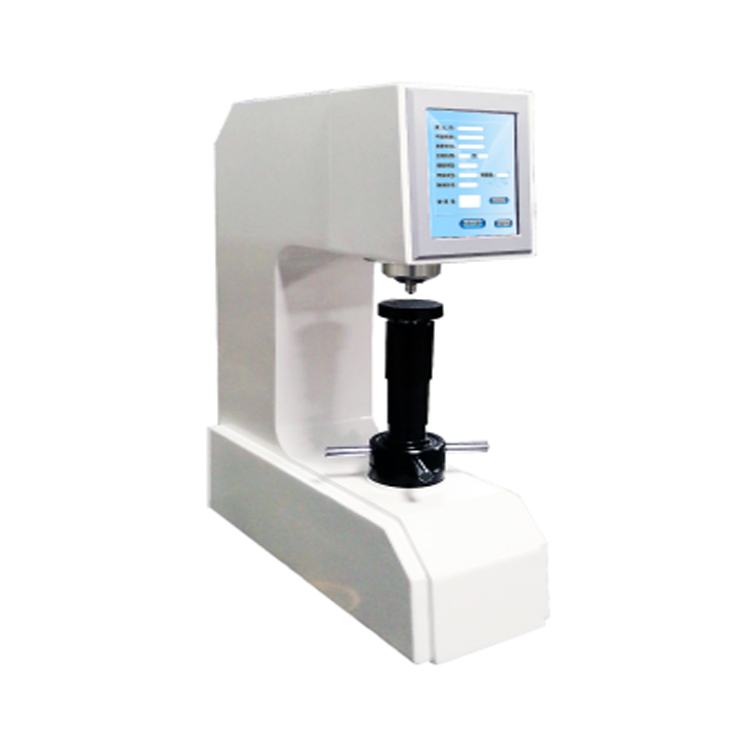

Main features:

Industry Impact

By combining speed, precision, and automation, this breakthrough technology sets a new benchmark for hardness testing in safety-critical components, aligning with global standards while enhancing operational efficiency.

Note: Specifications and capabilities are validated under ISO 6506, ASTM E10, and related industrial certifications

Core Features & Technical Advancements

- Rapid On-Site Hardness Testing: Compliant with GB/T24523 standards, the tester directly displays Brinell hardness values, enabling real-time quality assessment during brake pad production.

- Fully Automated Process: Integrated with closed-loop pressure control, the device automatically generates indentations, measures hardness, and retracts the indenter within 15 seconds per cycle, drastically improving efficiency.

- Precision Force Control: A 250 kg test load with <0.5% error, exceeding GB/T231.2 and ASTM E-10-08 requirements by 200%, ensures unmatched accuracy.

- Smart Data Management: Test results are saved in Excel format via USB, streamlining data traceability and analysis.

Key Applications

Designed for automotive manufacturing, this system addresses critical needs in brake pad hardness verification, supporting rapid quality checks without interrupting production lines. Its portability and automation make it ideal for industrial environments requiring high-throughput testing.Industry Impact

By combining speed, precision, and automation, this breakthrough technology sets a new benchmark for hardness testing in safety-critical components, aligning with global standards while enhancing operational efficiency.

Note: Specifications and capabilities are validated under ISO 6506, ASTM E10, and related industrial certifications